How To Specify A Desiccant Filter For A Storage Tank

Problem Statement

In the procedure of filling or elimination an atmospheric chemical storage tank, it is important that adequate ventilation points are provided at the meridian of the roof tank to discharge or collect air.

During the process of filling a tank with liquid, displacement of air inside the tank occurs, which is ordinarily termed as "out-animate" whereas the process of emptying is accompanied by air ingress, known equally "in-breathing". Frequent changes in ambient conditions often result in out-breathing and in-breathing scenarios, and such situations tend to be worsen in high humidity environment.

As out-breathing occurs, chemical gases, i.due east. sulfuric gas, may sometimes be discharged into the temper, which pose damage to people and the environment. As well, gases in the tank are likely to exist accumulated in shut proximity to the vent indicate hence resulting in corrosion in the detail area and prospectively forming explosive mixtures.

Design

It is a common practice to have the vent being located at the highest betoken of a tank of which pattern is in accord with the American Petroleum Constitute (API) Standard 2000, Venting Atmospheric and Low-Pressure Storage Tanks. The vent size shall be at least as large as the filling or withdrawal connection, whichever is larger but in no case less than ane 1/4″ nominal inside diameter.

The vent is equipped with a "goose neck" or another means to preclude the ingress of air or water into the tank. A bird screen is provided at the vent opening to prevent any entry of foreign insects, birds or objects into the tank. For vents with hazardous gases, a desiccant filter is attached to the goose-cervix.

DESICCANT FILTER

Desiccant filter is a unique air filter and water vapor prevention arrangement that refrains hazardous chemicals, i.e. concentrated sulfuric acid, from entering into a storage tank. It replaces the standard breather or ventilation system in practically all types of industrial equipment that contain hydrocarbon and other non-aqueous fluids. It also prevents contamination of products in storage tanks. The hygroscopic nature of concentrated sulfuric acid means that any moisture entering the tank will be rapidly absorbed into the acid. Over time, the top layer of acid volition go more dilute and become more corrosive.

The size of the desiccant filter required to protect a storage tank is determined past the corporeality of air and the charge per unit at which air enters the storage tank. More often than not, the rate at which the air enters equals the tank pump-out rate; however, in that location is an exception. A big tank that is nominally empty tin accept air entering the tank faster than the pump-out rate due to temperature and pressure changes. The desiccant filter is unremarkably sized to last from one to six months per charge.

Conventional vent ports or sabbatical caps provide little or no protection. They are typically rated at a higher micron size and do not have means of capturing moisture. Retrofitting these ports with desiccant breathers will provide full time protection against uninvited contaminants of clay and water.

Desiccant filter is filled with a h2o adsorbing agent that traps and adsorbs moisture contained in the air that passes the filter. The desiccant in this filter attracts and holds onto water molecules. A unmarried grain of silica gel is able to adsorb forty% of its weight in water. Information technology likewise removes moisture from inside the reservoir as the unit breathes out. As the tank heats upwardly, water contained inside the tank becomes h2o vapor. Equally the vapor is forced out through the breather, it is removed by the drying agent.

SIZING

At the maximum filling or pump-out rate, the dryer system including vent pipage should not create a high differential pressure that exceeds the design pressure level or vacuum pressure of the tank. Therefore, it is of import to size the dryer for the maximum in-breathing and out-breathing rates.

A tank that averages half full for a calendar month volition breathe 60% of its book per month with a 11.1°C (20°F) temperature change from day to night. Each 5.vi°C (10°F) increment or decrease in the temperature differential adds or subtracts some other thirty% to the volume.

BENEFITS

- Elimination of water contamination through the desiccant filter

- Removal of water contamination in the tank

- Prevention of rust and corrosion due to moisture ingress

- Prevention of contamination from inbound

- Extended tank life bridge

KEY FEATURES

- Quick and easy to install

- Visual color alter indication

- Resilient polycarbonate or glass sight window

- Available in flooring and wall mounting

- Refillable

SYNERGY'S EXPERIENCE

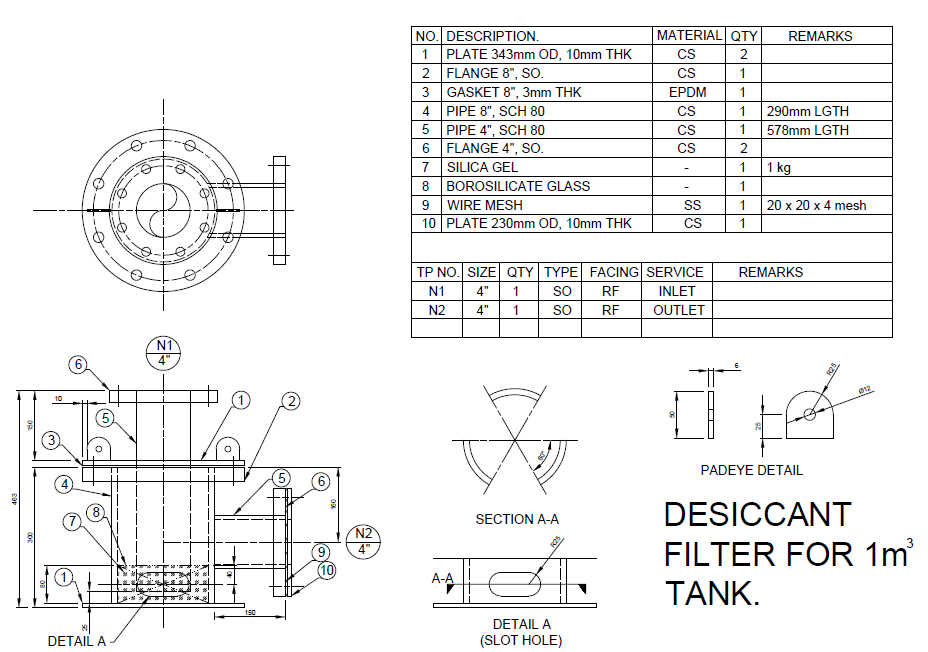

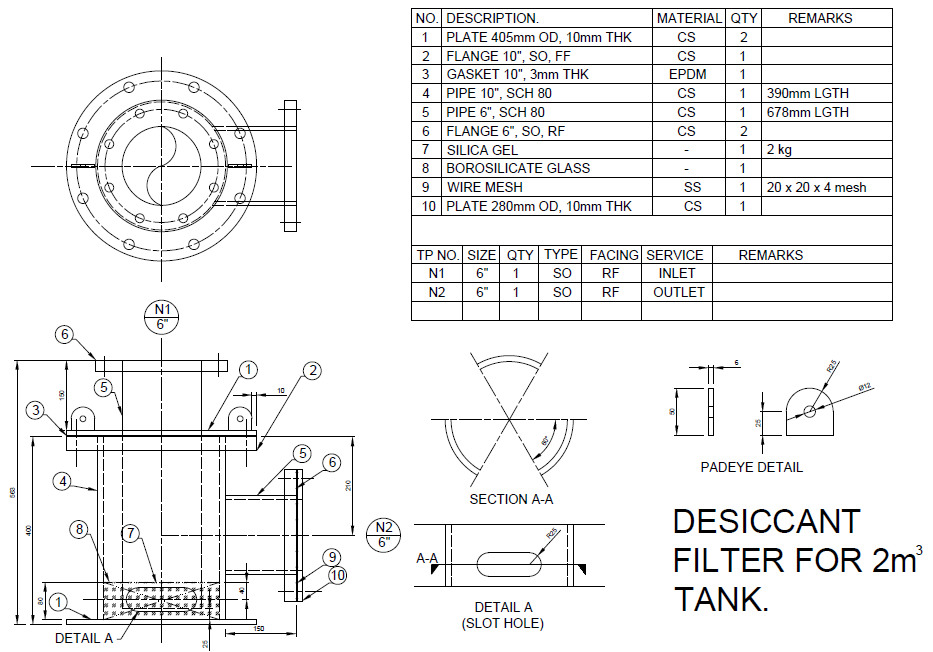

Synergy Applied science has studied, designed and synthetic a filter with functions like to a desiccant filter and has installed information technology on the project'due south sulfuric tanks.

How To Specify A Desiccant Filter For A Storage Tank,

Source: http://www.synergyengineering.com/insights/solution-for-product-out-breathing-and-in-breathing-in-atmospheric-tanks/

Posted by: hunsuckermilitaidele1997.blogspot.com

0 Response to "How To Specify A Desiccant Filter For A Storage Tank"

Post a Comment